- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Rumah > Produk > Konektor Mikroduk > Konektor Peredam Produk Mikro > Coupler Konektor Peredam Mikroduk Paduan Seng

Deskripsi Produk

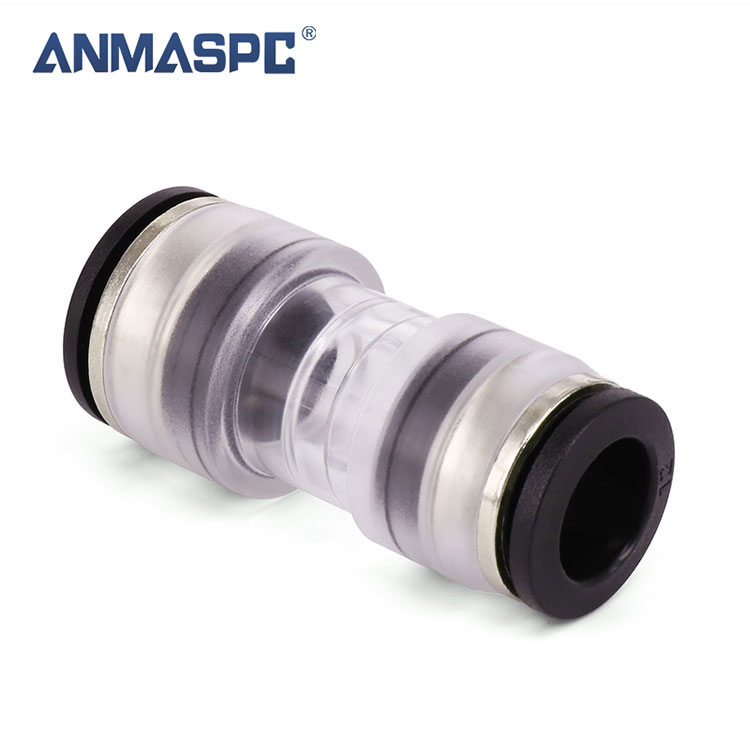

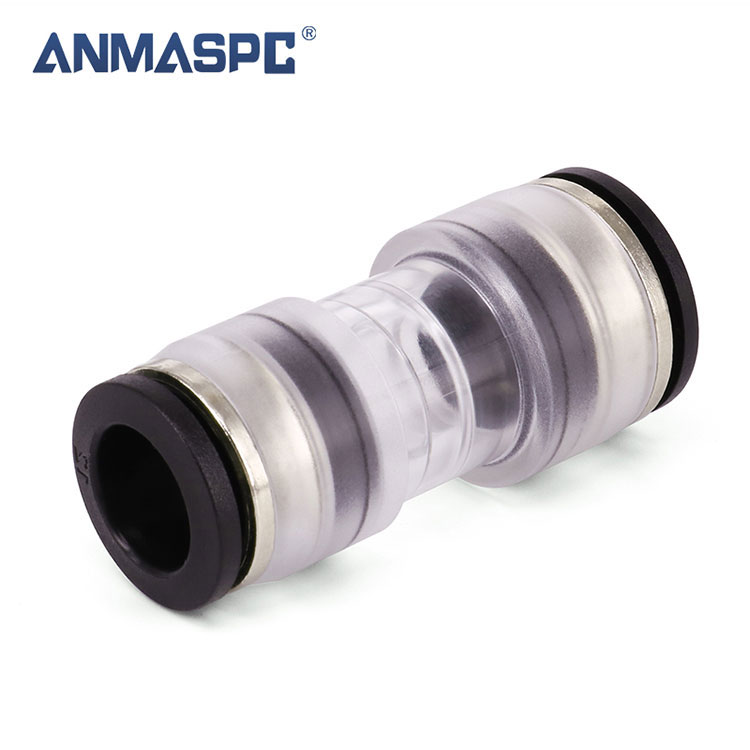

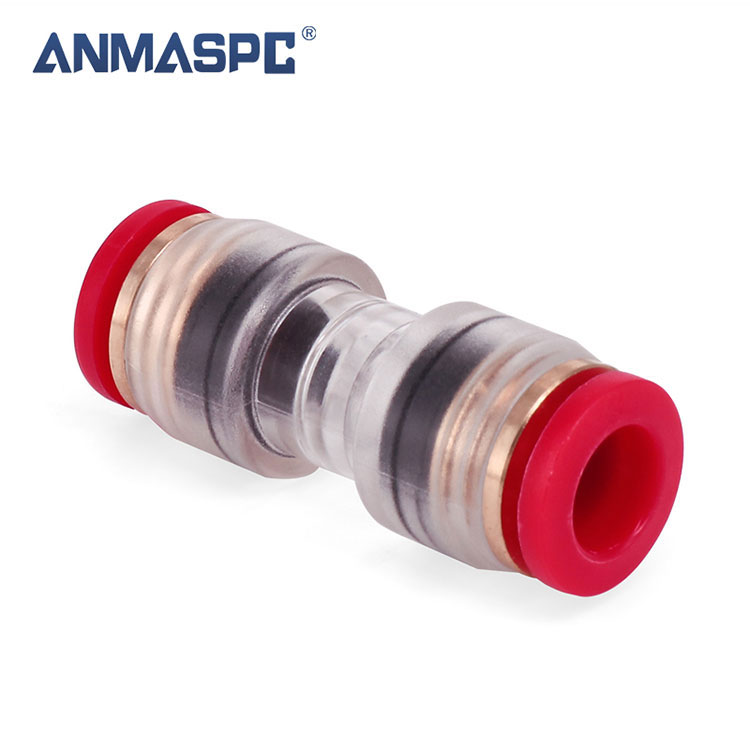

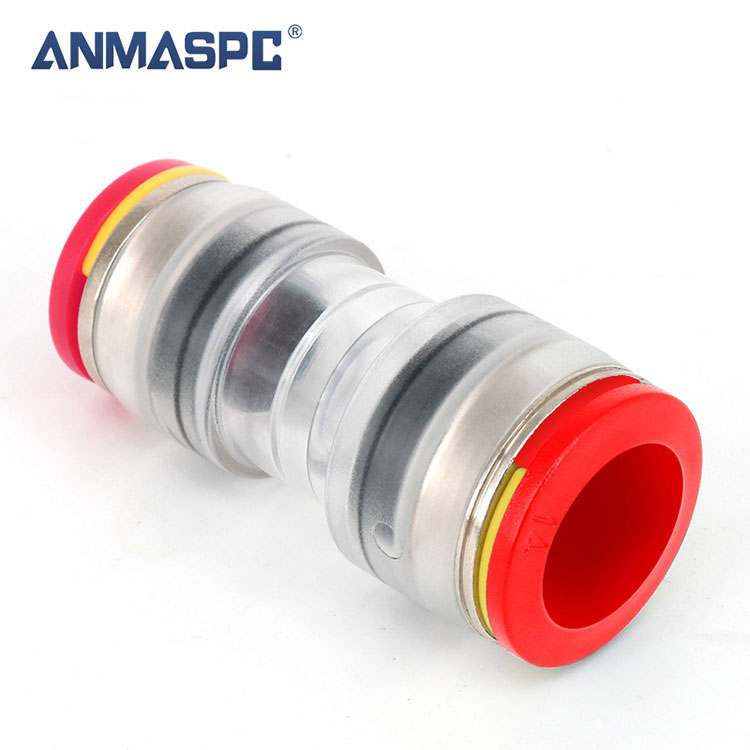

Coupler Konektor Peredam Microduct Transparan Paduan Seng Bodi Bening

Konektor pereduksi memungkinkan interkoneksi antara dua saluran mikro dengan diameter luar berbeda. Biasanya ini adalah kasus titik transisi dari saluran mikro DB ke DI yang memasuki rumah. Jika Anda belum menemukan ukuran yang tepat di antara BEBAS LOGAM atau DIPERKUAT, pilihlah salah satu dari ini.

FITUR UTAMA:

① Klip pengaman disertakan

② Teknologi push-fit

③ Tekanan Kerja: maks. 25 bar

Keterangan

|

|

Komponen | |||

| 1 | Collet | POM | |||

| 2 | Klip Pengunci | POM | |||

| 3 | Peluru | PADUAN ZINK | |||

| 4 | Kunci Cakar | SUS301/304 | |||

| 5 | Cincin Dukungan | POM | |||

| 6 | Cincin Segel | TEPI | |||

| 7 | Tubuh | PC2807 | |||

| Tabung Pas | |||||

| Pipa bahan | HDPE、PE、Nylon.Polyurethane | ||||

| Diameter luar pipa | Φ3,Φ4,Φ5,Φ6,Φ7,Φ8,Φ10,Φ12,Φ14,Φ16 | ||||

| Parameter Teknis | |||||

| Bekerja dengan cairan | Udara | ||||

| Keketatan | 0,15~0,8MPa Tidak Ada Kebocoran | ||||

| Tes tarik | 400N | ||||

| Tekanan bukti | 2.5MPa | ||||

| Kisaran tekanan operasi | 0~1,6MPa | ||||

| Suhu lingkungan dan suhu cairan | -40~60℃ | ||||

| Suhu Instalasi | -10℃/+50℃ | ||||

| Suhu Hembusan yang Direkomendasikan | -15℃/+35℃ | ||||

| Tingkat perlindungan | IP68 | ||||

| Kelas tahan UV | F1 | ||||

| Kekuatan penyisipan | Maks 50N (5kg) | ||||

| Masa hidup: | 25 tahun | ||||

| Standar: | EN 50411-2-8 | ||||

DAFTAR ARTIKEL

| Kode ANMASPC | Pipa OD/ID | Pipa OD/ID | Lubang meruncing |

| TPG5-3/2.1 | 5/3.5 | 3/2.1 | 3.5>2.1 |

| TPG5-4/2.8 | 5/3.5 | 4/2.8 | 3.5>2.8 |

| TPG7-3/2.1 | 7/5.5 | 3/2.1 | 5.5>2.1 |

| TPG7-4/2.8 | 7/5.5 | 4/2.8 | 5.5>2.8 |

| TPG7-5/3.5 | 7/5.5 | 5/3.5 | 5.5>3.5 |

| TPG8-3/2.1 | 8/6 | 3/2.1 | 6>2.1 |

| TPG8-5/3.5 | 8/6 | 5/3.5 | 6>3.5 |

| TPG8-7/5.5 | 8/6 | 7/5.5 | 6>5.5 |

| TPG10-5/3.5 | 10/8 | 5/3.5 | 8>3.5 |

| TPG10-7/5.5 | 10/8 | 7/5.5 | 8>5.5 |

| TPG10-8/6 | 10/8 | 8/6 | 8>6 |

| TPG12-7/5.5 | 12/10 | 7/5.5 | 10>5.5 |

| TPG12-8/6 | 12/10 | 8/6 | 10>6 |

| TPG12-10/8 | 12/10 | 10/8 | 10>8 |

| TPG14-10/8 | 14/12 | 10/8 | 12>8 |

| TPG14-12/10 | 14/12 | 12/10 | 12>10 |

| TPG16-10/8 | 16/13 | 10/8 | 13>8 |

| TPG16-12/10 | 16/13 | 12/10 | 13>10 |

Dimensi Keseluruhan

| Model | A | B | C | D | EC | ED | EA | EB | F |

| TPG5-3 | 33.6 | 6.1 | 10.0 | 11.1 | 12.0 | 12.8 | 3.2 | 5.2 | 2.3 |

| TPG7-3 | 36.4 | 6.1 | 10.0 | 11.1 | 4.1 | 154.0 | 3.2 | 72 | 2.3 |

| TPG8-3 | 36.4 | 6.1 | 10.0 | 11.1 | 14.1 | 15.4 | 3.2 | 8.2 | 2.3 |

| TPG7-5 | 38.2 | 7.6 | 12.0 | 12.8 | 14.1 | 15.4 | 5.3 | 72 | 3.7 |

| TPG8-5 | 38.2 | 7.6 | 12.0 | 12.8 | 14.1 | 15.4 | 5.3 | 8.2 | 3.7 |

| TPG10-7 | 41.5 | 9.0 | 14.1 | 15.4 | 17.5 | 18.3 | 7.3 | 10.3 | 5.7 |

| TPG10-8 | 41.5 | 9.5 | 14.1 | 15.4 | 17.5 | 18.3 | 8.2 | 10.3 | 6.3 |

| TPG12-8 | 45.3 | 9.5 | 19.2 | 15.4 | 19.2 | 20.7 | 8.2 | 12.3 | 6.3 |

| TPG12-10 | 47.3 | 15.8 | 17.5 | 18.7 | 19.2 | 20.7 | 10.3 | 12.3 | 8.3 |

| TPG14-10 | 50.3 | 14.0 | 17.5 | 18.4 | 22.2 | 23.0 | 10.3 | 14.3 | 8.3 |

| TPG14-12 | 50.6 | 18.0 | 19.2 | 20.7 | 22.2 | 23.0 | 12.3 | 14.3 | 10.3 |

| TPG16-10 | 48.5 | 14.0 | 17.5 | 18.7 | 24.7 | 25.1 | 10.3 | 16.2 | 8.3 |

| TPG16-12 | 52.3 | 18.0 | 19.2 | 20.7 | 24.7 | 25.1 | 12.3 | 16.2 | 10.3 |

Hubungi kami

Tag Panas: Coupler Konektor Peredam Mikroduk Paduan Seng, Cina, Produsen, Pemasok, Pabrik, Disesuaikan, Grosir, Penjualan panas, Kutipan, Harga Kompetitif, Populer, Tersedia

Kategori Terkait

Konektor Mikroduk Lurus

Konektor Peredam Produk Mikro

Blok Gas Mikroduk

Tutup Ujung Produk Mikro

Klip Pengunci Produk Mikro

Steker Saluran

Penutup

Cangkang Penutup Produk Mikro Hdpe

mengirimkan permintaan

Jangan ragu untuk memberikan pertanyaan Anda dalam formulir di bawah ini. Kami akan membalas Anda dalam 24 jam.

Produk-produk terkait